Injection Moulding

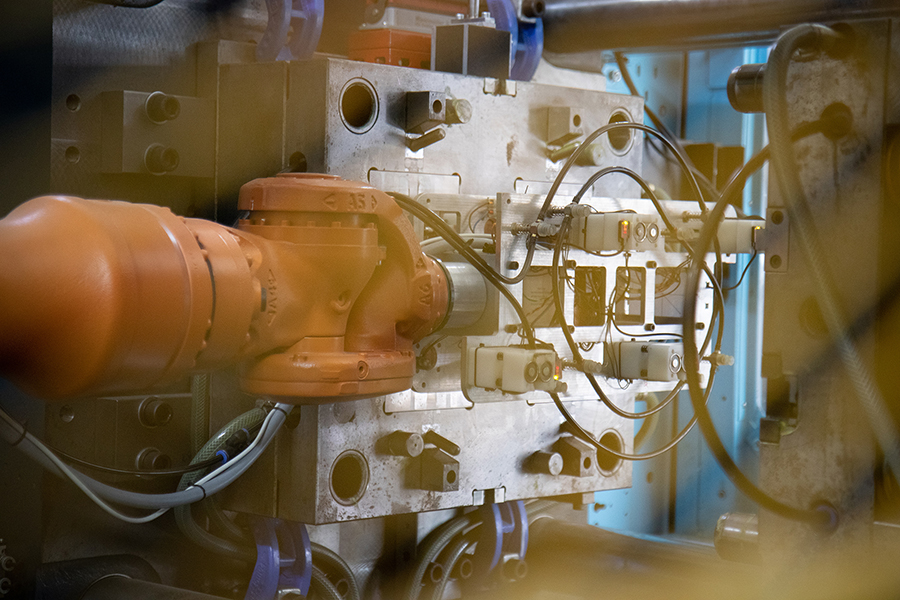

We have a wide range of injection moulding machines, consisting from 50 to 420 tonnes and from fully hydraulic to fully electric machines. Each machine is paired with a pick-and-place robot for improved productivity and for consistent product quality.

We are experienced in utilising a wide range of plastic resins, such as: AS, ABS, PBT, PC, PC/ABS, PMMA, PS, Nylon, Elastomers, and various additives & fillers.

Secondary Processing

In addition to plastic injection moulding, we are able to further customise our customers' products to their desired finishing. These include robotic spray painting, silk-screen printing, hot-stamping, pad-printing, ultrasonic welding, laser marking, and assembly services.

Automation

In addition to pick-and-place robots, we have invested in additional automation to such as 6 axis robotic arms for complex manufacturing tasks. In addition, we have introduced cavity separation automation for key clients to improve processing capabilities.

With our in-house automation team, we have developed solutions for our customers to meet their stringent needs.

Tooling

On site are a wide range of tooling equipment to aid in producing accurate precision tools for our customers. These include a range CNC milling and EDM machines, capable of servicing with copper and carbon inserts.

Quality

In this day and age, quality is paramount. We are committed to ensure that only quality parts reach our customers hands. Our quality assurance tools range from Coordinate Measuring Machines (CMM) to fully automated 2D optical vision measuring systems. In addition, our processes are fully backed by ISO 9001:2015 certification.